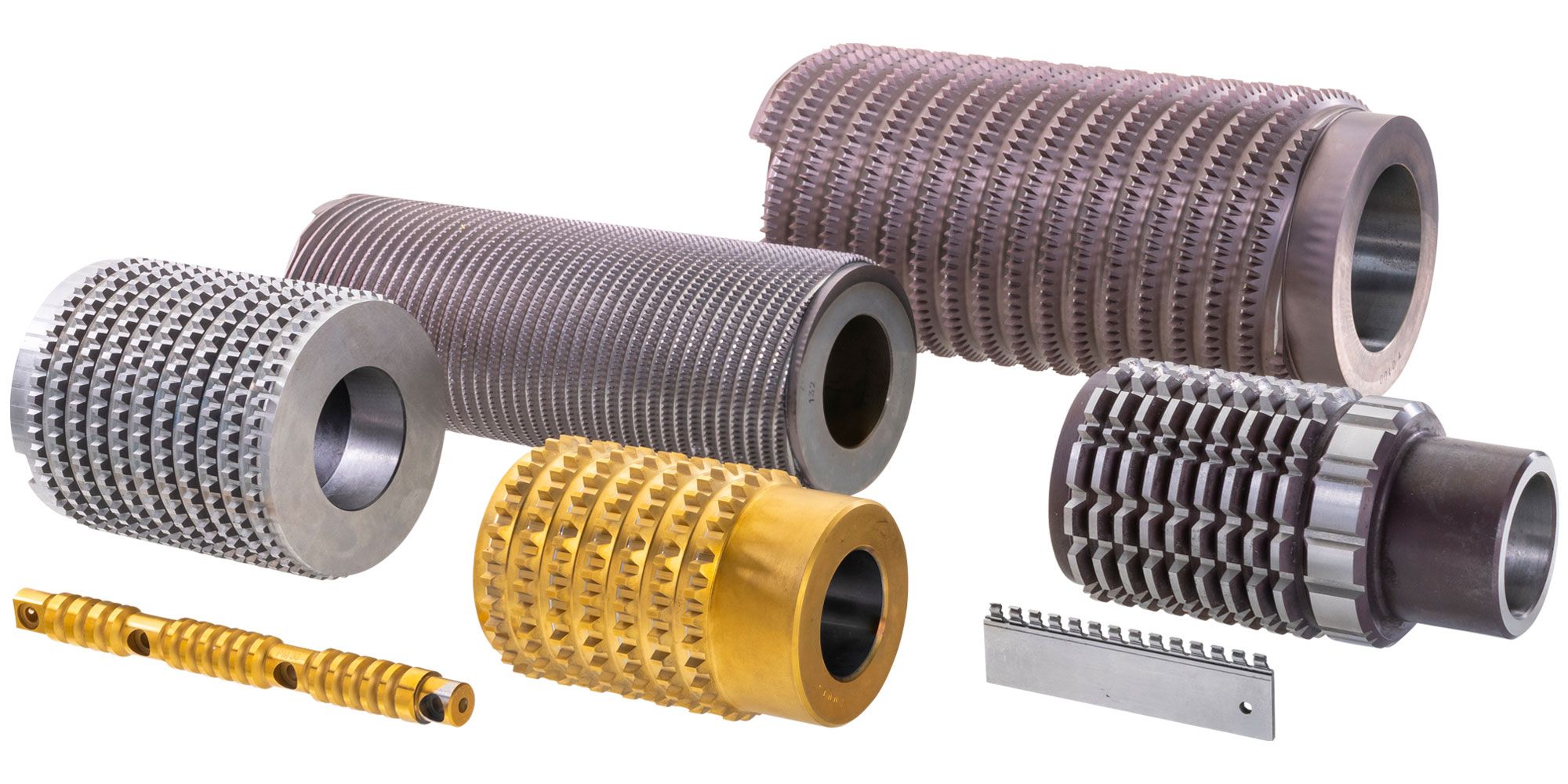

Broaching tools

Broaching is a machining process for the production of internal and external profiles using a broaching tool with a staggered increase in the size of the cutting teeth.

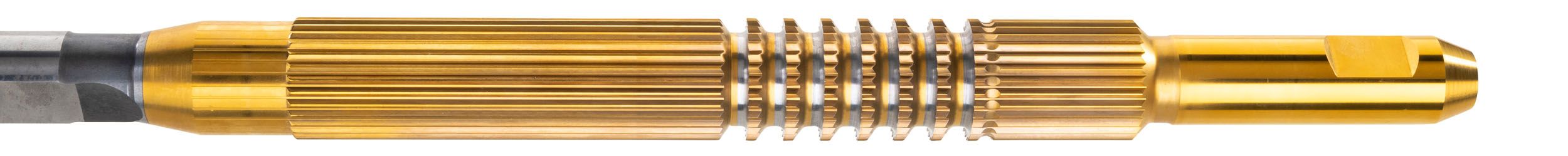

Internal broaching tools

Interior broaching involves clearing the interior surfaces from a passage.

Hard broaching: After soft broaching and hardening the workpieces, hard broaching is usually carried out with a defined amount of material added. The broaching speed is at least 60 m/min. using a special broaching tool with one or two coated hard metal bushings.

Twist broaching / inclined broaching: Helical internal profiles are cleared using twist broaching tools. In this case, the twist broaching tool or the workpiece is usually rotated in a defined manner over the broaching stroke.

Dry broaching: Dry broaching refers to broaching without cooling lubricants at a broaching speed of usually 30 m/min using coated broaching tools.

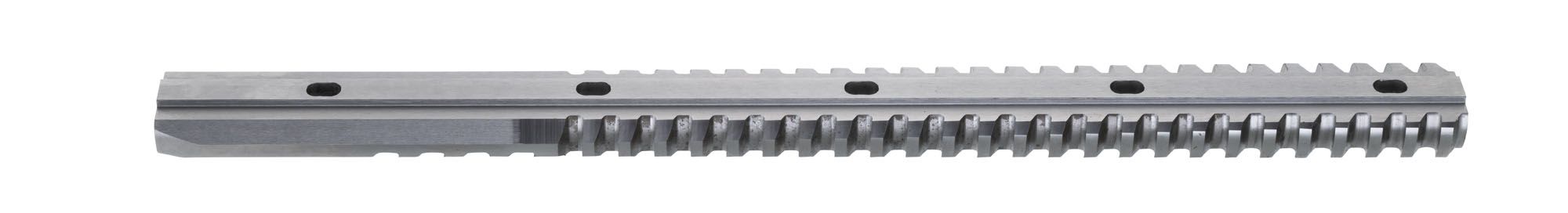

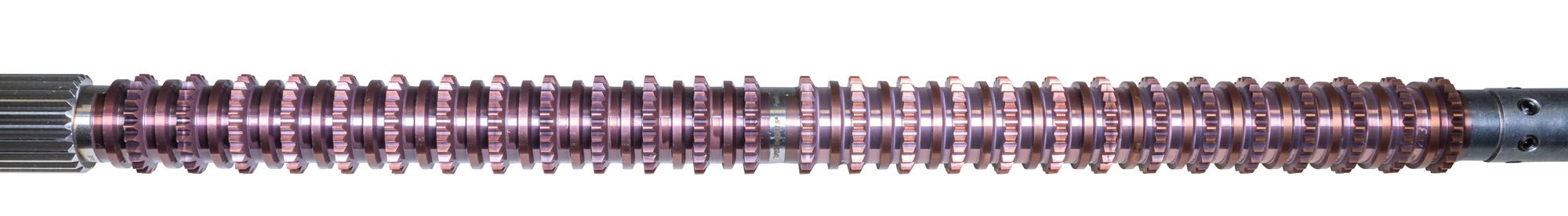

Exterior broaching tools

With external broaching, external surfaces are broached. In contrast to internal broaching, the workpieces are usually clamped in order to compensate for the displacement forces. The process is used to attach external profiles to, for example, connecting rods and covers, gear racks, steering pinions, shift rods, bearing grooves on engine housings, cross flanges, etc.

Special broaching tools

Special broaching tools are customized tools for specific requirements in metalworking. They are designed and manufactured to meet individual requirements. They optimize work processes, enable precise work and increase the efficiency of the customer's production. By adapting to customer requirements, special broaching tools offer innovative solutions for various industries.